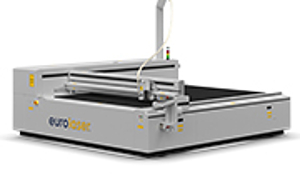

Eurolaser Laser Cutting Systems

Contactless Cutting, Excellent Edge Quality, German Engineering

Eurolaser is one of the world leaders in CO₂ laser cutting technology. With its contactless operating principle, superior edge quality and wide format production options,

it offers unparalleled results in acrylic, textile, plastic, wood and composite materials.

Superior Precision in Non-Contact CO₂ Laser Cutting

Eurolaser systems cut materials without physical pressure thanks to contactless CO₂ laser technology.

This results in smooth, dust-free, and burn-mark-free edges, especially on acrylic, textile, plastic, and wood surfaces.

With high-power laser tubes (60–600 W) and precise optical systems, cutting, marking, and engraving can be performed on the same platform.

Developed with German engineering, Eurolaser systems combine excellent quality on every material with low maintenance costs.

Designed for Contactless, Fast and Flawless Production

Contactless Cutting Technology

Production without physical contact and without deformation. No knife marks, cracks, or stresses occur on the material.

Multi-Purpose Use

Three functions in one platform — versatile production by using the power of the laser at different levels.

Excellent Edge Quality

Acrylic, textiles, and plastics achieve a smooth finish without burn marks. No additional finishing is required.

Data and Software Integration

Direct integration with Onyx, Caldera, and CAD/CAM systems. Laser processing parameters are managed digitally, and production can be monitored.

Camera-Based Contour Tracking

Automatic alignment and precise cutting by recognizing pressure marks. Repeatable accuracy, minimum waste.

Low Maintenance, Long Lifespan

Stable performance with sealed optical path and water-cooled laser tubes. Minimum downtime, maximum continuity.

Energy Efficiency, Minimum Waste, Maximum Quality

Eurolaser systems ensure minimum waste, low energy consumption, and environmentally friendly production in the manufacturing process. Thanks to the contactless cutting method, material waste is reduced, and a clean production environment is maintained. In addition, the laser’s CO₂-based structure does not require the use of solvents or chemicals — ideal for sustainable production.

Eco Friendly Production

Low Energy Consumption

Long Equipment Lifespan

A sustainable investment with durable components.

Eurolaser Product Family

Laser power, speed, and precision options to suit every production scale.

- Working area (W x D): 3210 x 3200 mm

- Laser power: Between 60 and 450 Watts

Experience Eurolaser Technology Firsthand

At the Mat Kağıt Demo Center, you can see Eurolaser systems live and test them with your own material samples. Our expert team will help you determine the most suitable laser configuration for your production needs.